Product Development

inTEXive has acquired experience in developing new products in various fields. As technical textiles and composites are relatively new materials, inTEXive’s goal is to support the development of such industries in the MENA region. Our expert product development team can help in the design and development of new products which utilize these advanced materials. We can assist your product development activities at any stage from conception to commercialization.

Our partner institutions are equipped with state-of-the-art prototyping and testing equipment for technical textiles, nonwovens, and fiber composites. Moreover, our team of engineers are well versed in process development, pilot production, and scaling-up the production process.

Our services include:

- 3D CAD Modeling and Product Design

- Prototype Development

- Product Evaluation

- Process Development and Evaluation

- Pilot Production

Heat and soil resistant women Abaia

Previous Projects:

- Developing the world′s first textile palm fibers and reinforcements, PalmFil

- Developing Fire Resistant Spun Yarns, Mediterranean Textiles Company (Medtex) S.A.E

- Product Diversification Study with Focus on Technical Textiles, Mediterranean Textiles Company (Medtex) S.A.E

- Developing new technical products from flax wastes for industrial applications and for making cottonized flax

- Producing composites panels as alternative for MDF Panels from TetraPak waste and other industrial and agriculture wastes.

- Developing premium underwear (NanoTex) made of 100% fine Egyptian cotton. treated with silver Nano particles for antibacterial effect and soil resistance.

- Developing premium women Abaia, with heat and soil resistant properties in partnership with Areka Advanced Technologies Turkey.

- Partnering with an international firm to produce a proprietary tubular woven reinforcement for flexible pipes.

- Partnering with Eastman Naia™ cellulosic yarn to develop fabrics and apparel for the MENA region.

- Managing Textile incubators for startup and SMEs.

- Developing nanofibers with solution blowing spinning technique.

- Developing 3D preforms with complex shapes for composite applications (I-beam, light pole, oars, and wind mill blades).

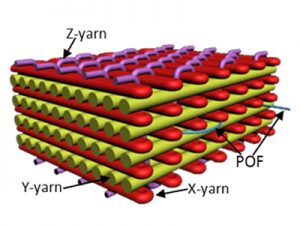

- Developing composite plates with embedded optical fiber for structural health monitoring system.

- Nano Sensors based on Nanofibers for ammonia monitoring.